This

is not a secret that the best floor covering looks beautiful and elegant only

when it was installed technologically right. In this article you could find

guidelines for correct installation of Quartz-vinyl coverings.

This

is not a secret that the best floor covering looks beautiful and elegant only

when it was installed technologically right. In this article you could find

guidelines for correct installation of Quartz-vinyl coverings.

Installation guidelines

Guidelines for installation of quartz-vinyl tile

Quartz-vinyl tiles need to be installed on smooth, clean (without sand, dust, oil, fat, polishing materials, paint) and dry sub floor (base). Coverings do not absorb moisture, therefore if they are glued to insufficiently dry base the moisture will accumulate under materials and destroy covering and adhesive. Relative humidity of floor can be measured by hygrometer, thus for quartz-vinyl coverings it should not exceed 0,05 %. On concrete base of ground floors and in wet premises (on the kitchen, for example) moisture proofing is necessary.

While installing �warm floor� heating system is to be switched on at least 4 weeks prior to covering installation, but it should be switched off for 24 hours prior to any preparation of surface for installation. The temperature of heating of �warm floor� should not exceed 280С.

After check of humidity and horizontal position of surface, it is possible to start installation of covering.

To install covering professionally and with minimum expenses it is necessary to use special tools. For cutting you will need special knives with disposable blades: trapezoid blades for marking and hook-shaped for final cutting. To determine how much material you will need it is necessary to know length and width of premise. At diagonal installation there is a lot of waste in comparison with parallel; in beveled or round premises there is more waste than in the right-angled ones.

Quartz-vinyl covering should be glued very thoroughly.

While gluing it is necessary to avoid hitting of air on the base of covering (there should be no air under covering). It is forbidden to install material right up to walls there should be a small gap. To apply adhesive uniformly and in that quantity which is necessary for installing of each very type of covering it is necessary to use notched trowel with disposable blades. Due to the various shapes and �steps� of trowel notches the necessary consumption of adhesive is provided.

Having glued the covering, it is necessary to roll it with the help of special heavy roller or to lap it with cork plank. It is done for deleting bubbles and for the best gluing.

For gluing of quartz-vinyl coverings it is necessary to use acrylic dispersing adhesive or adhesive recommended by the company-manufacturer, otherwise covering could be spoiled. Our company has a wide range of adhesives of national and import production for PVC and quartz-vinyl coverings.

Please note adhesives for quartz-vinyl coverings has �wait time� about 5-10 minutes, i.e. the covering can be glued only after adhesive on the base is ready. You could find all necessary information about these characteristics on adhesive packing.

After quartz-vinyl covering is glued, it is not necessary to make special processing of junctions except for especially wet premises, for this purpose cold welding is applied. For hot welding special cord of one color or contrasting (if it is required by design) is used. Sealing of joints should be made after adhesive is gripped, i.e. not earlier than in 48 hours after installation when you use dispersing adhesive. If joints are sealed too early it will have a negative affect on gluing and can lead to defects of joint edge.

If you do not have time or desire to be engaged in installing of floor coverings you could take advantage of our service.

Installation of veneer.

All humid operations should be finished before installation. Water-proof veneer of 12-15 mm width is applied. Veneer sheets are cut on 50х50 cm pieces (but no more than 50х70 cm) and installed with the help of mastic or adhesive. Veneer is fixed with dowel, it is necessary to use not less than 5 dowels for one piece of veneer. After installation polishing and wet cleaning of premise is made. Humidity of veneer base should not exceed 8-10 %, this is important to avoid deformation which could lead to parquet covering deformation. Color change or deformation of parquet covering could be caused by high humidity of the base, displacement of its units, heat up more than 30 C. (due to the fact that there are heating pipes in the floor) or dirtying of floor by oil, paint, bitumen, etc.

Preparation. Filling.

If the base is far from ideal (gaps, breach of cracks, small surface imperfections) this problem is easy to solve if you use quick-set pitch Thomsit R726 and repair mixture Thomsit RS88 (for bigger dints), which could be used on vertical and horizontal surfaces as well as for repair of ladders. If there are surface imperfections of several centimeters size it is recommended to use a concentrate for making quick-set screed coverings (this will safe your time and money) - Thomsit SE93 (it is mixed with sand in 1:5 ratio).The base fulfilled by these substances is ready for further processing in 24 hours.

Preparation. Padding.

Padding of surface is the integral process of preparation system. Primer is necessary for increasing of adhesion of self-leveled and repair mixtures to the base, regulation of absorbing properties of the base and for strengthening of moisture proofing. Thomsit R777 is applied on concrete, cement and anti hydride sub floors; xylite and magnesia base should be processed with Thomsit R755 which could also be used as a waterproofing barrier as well as lock for capillary moisture. Thomsit R760 is applied on nonporous, unabsorbed base (stone floors, ceramic tile); it is intended for processing of wooden base and self-leveled mixtures before application of dispersing gluing components.

Leveling

Without application of self-leveled mixtures it is impossible to make ideal base. Possible surface imperfection of the base is on the distance from 10 m - up to 12 mm. If filling was done right, optimal width of the self-leveled mixture should not exceed 1-10 mm. Thomsit offers a wide range of self-leveled mixtures for solution of any problem for any base. Materials could be applied in apartments and shops, offices and business centers. Readiness for installation of floor coverings is in 24 hours.

Thomsit DD - self-leveled mixture for leveling of the base before installation of linoleum, carpet and laminate at normal loads in dry premises with the layer of 0,5-5 mm.

Thomsit DX - self-leveled mixture for leveling of the base before installation of linoleum, carpet, parquet at average loads in dry premises with the layer of 0,5-10 mm.

Thomsit FA97 - self-leveled mixture reinforced by a fiber for leveling of the base before installation of any of any coverings at big loads in dry premises with the layer of 3-15 mm. Flexibility, suitable for mobile wooden base.

Thomsit EA99 - high-strength express self-leveled substance for premises with heavy loads, readiness for installation in 3-4 hours.

Thomsit SL 85 � universal elastic self-leveled mixture for leveling of wooden, concrete, cement, cement-sand and asphaltic concrete base. Width of a layer for one plotting is 0,5-50 mm. Suitable for deformable bases (wood overlaps, etc.).

Thomsit SE 93 - universal quick-set mixture for installation and renewal of the base, different types of screed coat subject to mechanical effects. Can be used as heated layer.

Installation - gluing of coverings.

Trade mark Thomsit offers a wide range of adhesives for installation of floor coverings.

Adhesives for flexible coverings.

Thomsit T4400 - dispersing adhesive for textile coverings with and without a base, it is necessary to use dispersing adhesive Thomsit UK4000 for especially hardly installed coverings, it was developed for gluing of homogeneous and heterogeneous PVC, textile coverings with normal or foamed base made from latex, PVC or textiles, cork covering on the basis of PVC. Thomsit K188E is applied for damp, adhesion, contact gluing of any types of PVC, polyurethane, cork covering, rubber and polyolefin on horizontal and vertical surfaces; it is suitable for gluing of PVC on PVC and recommended for use on strong-loaded heavy-duty projects. For thick and hard rubber coverings it is recommended to use Thomsit K172 or Thomsit R710. Thomsit K172 is applied for gluing of cork coverings and vinyl, carpet coverings on stair flights, for adjustment of plinths. Special adhesive Thomsit L240D which perfectly glues covering and does not destroy natural materials could be used for tiles and rolls from natural linoleum.

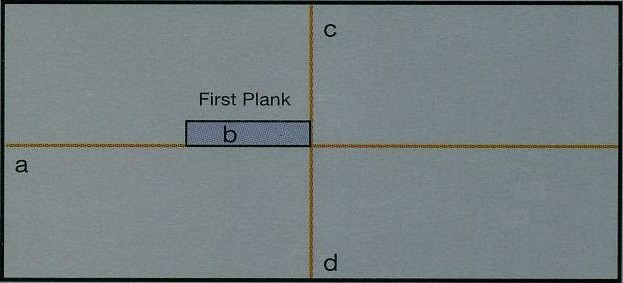

The scheme of stacking of a quartz-vinyl tile

The stacking starts from center of putting. A central point of putting in the beginning is planned and the ruler guides of stacking are carried out. Then the first tile is stacked.

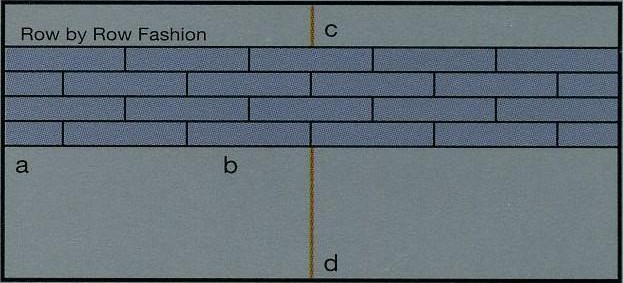

After that by a method of "pyramid" some inexact layers of a tile.

Then the method "Row by Row " stacks full numbers of a tile.

After that the method of "pyramid" spreads some inexact layers and so on.

The excision of a tile near walls of putting and "interruptings" implements a clerical knif: the upper (protective) layer is chased, then through link of retrosection the tile cracks and is sawed from a back side. The tile is cut up also easily, as a plaster cardboard. The shaving of a tile on prefabricated templets, for example, from an arboreal fibre board is possible, if "interrupting" has very composite shape (for example, - string, step of the composite shape, tube etc.).

GUIDELINES FOR SUBSTANCES

Primer for preparation of the base from wood, flakeboard, veneer:

UZIN-PE 260. Dispersing primer. i

UZIN-PE 317. Adhesion primer on the basis of dissolvent. Cold-resistant, anhydrous, interpenetrating, suitable for surfaces sensitive to moisture.

CERESIT CT 17. Strengthens base surface; reduces absorbing ability of the base.

Primer for preparation of the base from concrete and prefabricated screed coats.

UZIN-PE 317. Adhesion primer on the basis of dissolvent. Cold-resistant, anhydrous, interpenetrating, suitable for surfaces sensitive to moisture.

THOMSIT R777. Dispersing, penetrating dust tying primer.

CERESIT CT 17. Strengthens base surface; reduces absorbing ability of the base.

CERESIT CN. Universal primer.

Adhesive for tile installation.

UZIN-КЕ 2000S. Dispersing adhesive for elastic coverings. Universal, can be used like "wet" and as contact, resistant to plasticizers.

UZIN-КЕ 2428. Quick dispersing adhesive.

THOMSIT UK 4000. Universal dispersing adhesive.

THOMSIT K-188Е. Dispersing adhesive, ecologically safety.

TEKS. Acrylic adhesive.

Rubber-bitumen mastic.

Download guidelines in *.doc format (470 KB)